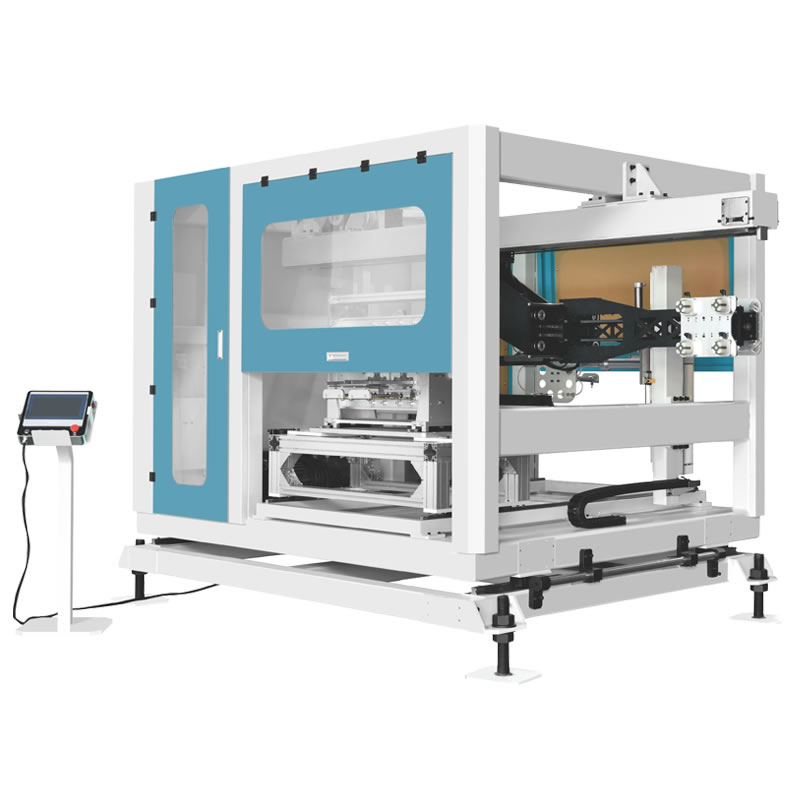

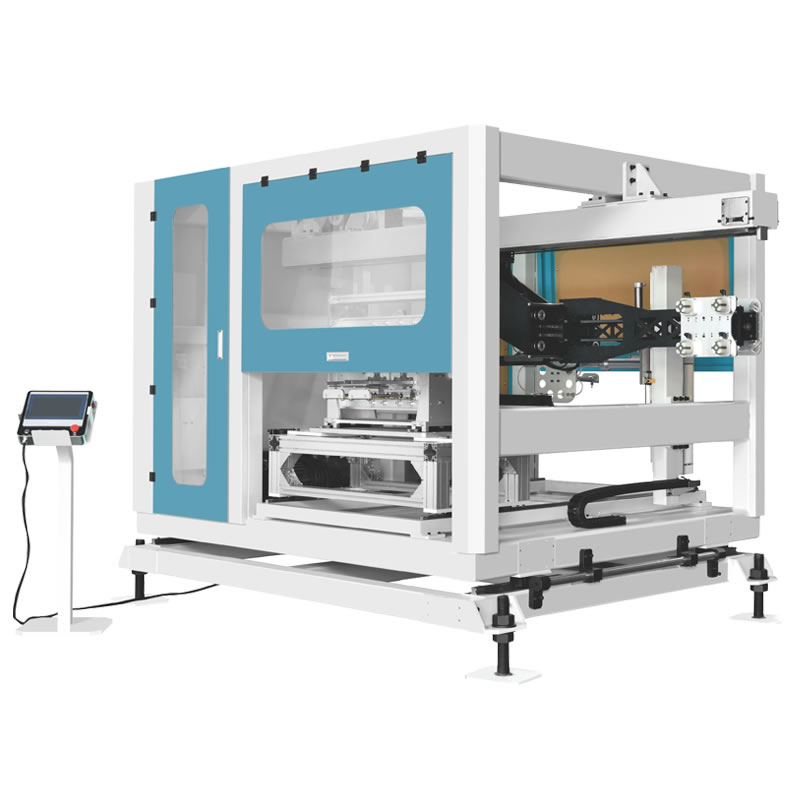

◎ Application for: Paint bucket, milk tea cup, yogurt cup and fast food box labeling

◎ Injection molding machine: 250T~350T

◎ In time: 0. 6~3 seconds

Side entry In mold labeling system (IML) is a technology that directly embeds tags into injection molds. Its working principle and process flow are as follows:

Principle of Working 1. Label Preset: The label is taken out of the label library through an automated system (such as a robot) and placed accurately at the designated location of the mold.

2. Mold closure: The mold is closed and the label is fixed to the inner wall of the mold.

3. Injection molding: Molten plastic is injected into the mold, closely combined with the label to form a product with a label.

4. Cooling and mold opening: After the plastic is cooled, the mold is opened, the finished product is ejected, and the label is firmly embedded in the product surface.

Process flow 1. Label preparation: - Label printing: Print patterns and text according to requirements.

- Label cutting: Cut into the desired shape and size according to specifications.

2. Label conveying: - Tag library: Store pre-cut labels.

- Manipulator: Remove the label from the label library and feed it to the mold.

3. Mold positioning: - Label placement: The robot places the label accurately on the inner wall of the mold.

- Tag fixing: Fix the label by vacuum adsorption or electrostatic adsorption.

4. Injection molding: - Mold closure: Ensure the correct position of the label.

- Plastic Injection: Modified plastic injection mold, combined with label.

- Cooling and curing: Plastic cooling, the label blends with the product.

5. Open mold pickup: - Mold open: The mold opens after cooling.

- Eject the finished product: The ejection mechanism ejects the finished product.

6. Post-processing: - Quality inspection: Check the position and appearance of the label.

- Packaging and storage: Qualified products are packaged and storage.

Side-in IML system achieves efficient combination of labels and products through automated label conveying and precise injection molding. It is widely used in food, daily chemicals, medicine and other fields to enhance products Appearance and productivity.

Follow us