What are the commonly used wire harness ties? After we purchased the labeling machine, the maintenance of the fully automatic in-mold labeling machine is also the most concerned issue for many customers, because once the machine fails, It will affect all aspects of the product production, resulting in a decrease in the quality and output of the product. This problem requires us to pay more attention to it in daily life. Standardized operation, and reasonable maintenance of the labeling machine should be carried out to avoid machine failure. After we maintain it, the machine will be able to operate normally and for a long time, and it will not affect the production tasks and product quality of the machine.

Westermo Technology lets us understand the maintenance skills of fully automatic in-mold labeling machines, so that the labeling machines can perform better and extend their service life.

Tips for maintaining fully automatic in-mold labeling machine

1. Maintaining fully automatic in-mold labeling machine must be done well. The labeling machine can easily absorb dust during operation, so you must regularly clean the dust on the labeling machine. When the labeling machine is temporarily idle, we should unplug the power supply and cover it with a dust cloth to prevent the dust from falling on the labeling machine. In addition, the high-temperature belts of fully automatic labeling machines must also be regularly decontaminated, so as to better ensure the high-quality operation of the labeling machine.

2. Do not forget to apply some lubricant when maintaining the labeling machine. The labeling machine should apply a certain lubricant after operating for a long time. Many parts in fully automatic labeling machines, such as gears, bearings and gearboxes, are prone to rust and wear after use for a period of time, and lubricating oil can ensure that all parts of the labeling machines are smooth. Professional personnel Everyone knows that the labeling machine should apply some lubricant after working continuously for more than 48 hours. The fully automatic labeling machine should be maintained regularly after operating for a certain period of time. On the one hand, it ensures that the labeling machine has a good operating effect, and at the same time it can extend the life of the labeling machine.

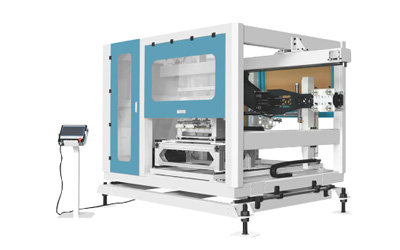

Dongguan Westmore Technology Co., Ltd. was established in Hongyuxing Technology Park, Dongkeng Town, Dongguan City. It is professional in intelligent molding internal labeling system (IML) and injection molding and blow molding automated production systems.

Follow us